A still From Tesla’s battery manufacturing video.

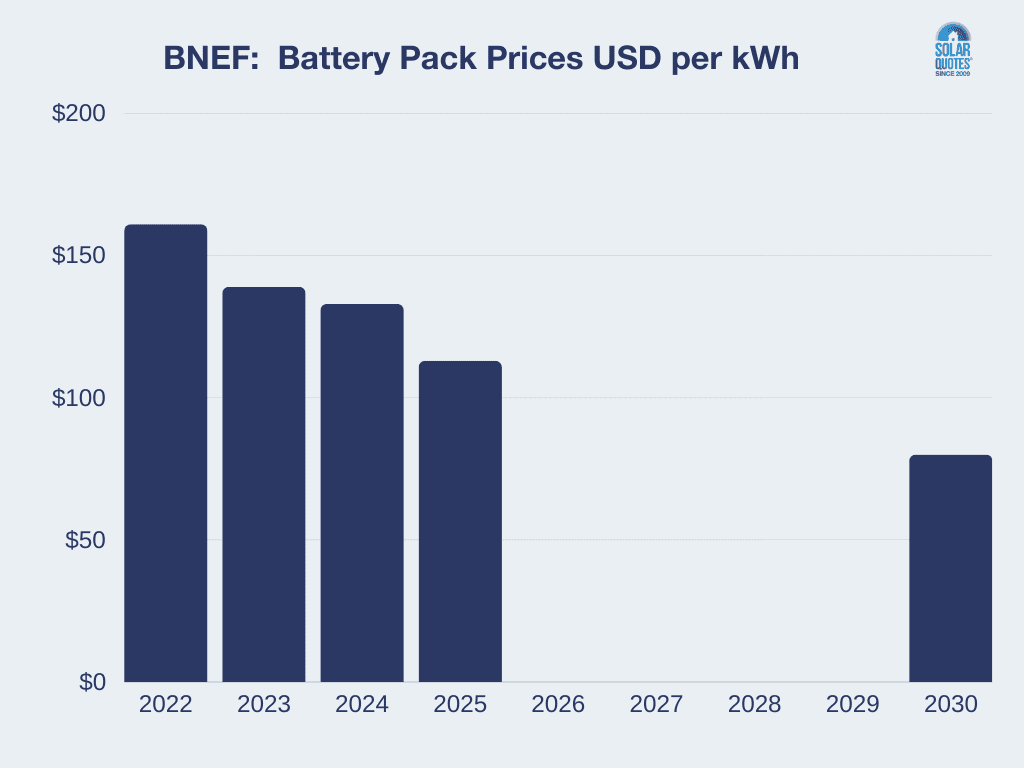

Battery prices have begun falling again after rising during 2022, according to Bloomberg New Energy Finance (BNEF).

According to analysis announced yesterday, BNEF says average lithium-ion battery pack prices have dropped to US$139 per kilowatt-hour after ending last year, hitting $161/kWh.

The US$139/kWh price represents a record low, BNEF says.

And there are more price falls to come, with BNEF predicting that nickel, lithium and cobalt prices will fall next year.

The company said by 2024, the pack price could be at $US133/kWh, $113 in 2025, and as low as $US80/kWh by 2030.

What’s behind the falling prices? Three main factors: raw material and component prices fell as production capacity grew; demand fell short of some industry expectations; and the take-up of lower-cost cathode chemistries.

Surprisingly, battery prices continue to fall despite huge demand growth: BNEF said demand across the EV and stationary storage markets grew 53% year-on-year, reaching 950 GWh in 2023.

China enjoyed the lowest prices in the world, at around $US126/kWh, with prices in Europe 11% higher and 20% higher in the US.

China’s prices, BNEF said, were driven by manufacturers ramping up production to grab their slice of the growing market.

The world’s manufacturers are also adopting new and cheaper technology.

LFP Cells 32% Cheaper Than NMC

The type of lithium-ion battery affects cost. Lithium iron phosphate (LFP) cathode technology is the catalyst here: battery packs come in at $US130/kWh and cells at $US95/kWh.

BNEF said this is the first time LFP has dipped below the $US100 mark, and on average LFP cells cost 32% less than those using lithium nickel manganese cobalt oxide (NMC) cathodes.

That’s promising for the upcoming Tesla Powerwall 3 pricing, which is said to use LFP cells.

EV Battery Packaging Gets Cheaper Too

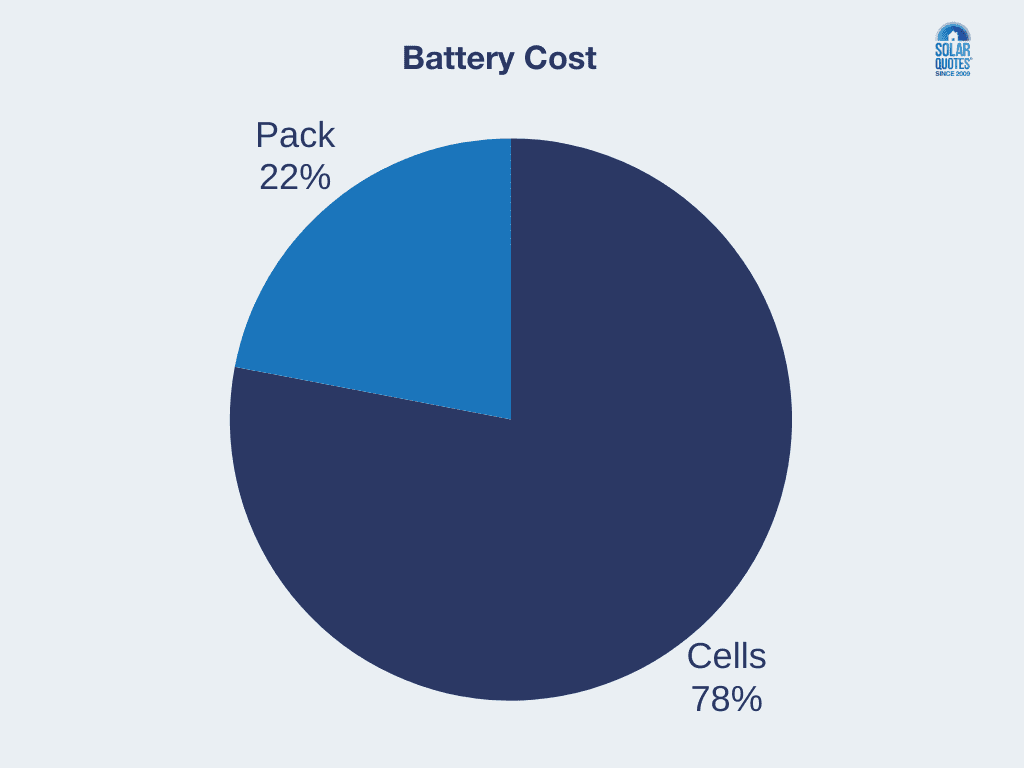

EV battery packs averaged $US128/kWh. Battery cells averaged $US89/kWh.The cell-to-pack ratio in EVs has gone from 70% : 30% to 78% : 22%. In other words, assembling the battery cells into packs is getting cheaper.

EV battery cells are getting cheaper to assemble into packs.

The only cloud on the horizon in BNEF’s predictions is the impact of politics, with policies encouraging local manufacturing (in the USA and Europe) and raising the spectre of higher costs.

As BNEF explained, battery manufacturers in those blocs are impacted by energy, equipment, land, and labour costs – all higher than in Asia.

However, the analyst firm said it had not modelled the $US45/kWh production tax credit under America’s Inflation Reduction Act.

As for when the battery cell and pack price reductions will make home batteries cheaper, your guess is as good as mine.

RSS - Posts

RSS - Posts

Ok, but how does this / will it affect prices here in Australia?